Yijiang Machinery Awarded ISO 9001 for Global Leading Extendable Track Systems Export Quality

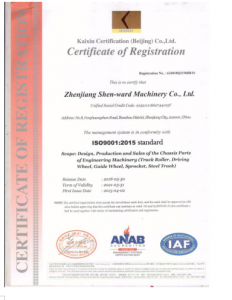

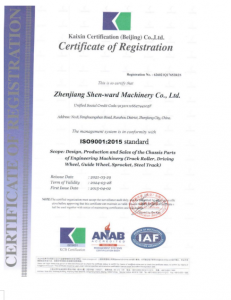

JIANGSU, ZHENJIANG, CHINA, January 23, 2026 /EINPresswire.com/ -- Zhenjiang Yijiang Machinery Co., Ltd., a specialized manufacturer with nearly two decades of expertise in crawler technology, has formally announced its successful attainment of the ISO 9001:2015 certification. This international accreditation serves as a formal validation of the factory's quality management protocols specifically applied to its high-capacity walking systems. As a Global Leading Extendable Track Systems Exporter, Yijiang Machinery designs and manufactures specialized undercarriages featuring hydraulic width-adjustment mechanisms. These extendable track systems allow heavy machinery to remain compact for road transportation while expanding their footprint on-site to ensure maximum stability. The certification highlights the organization’s ability to meet rigorous international standards while exporting customized steel and rubber track solutions to over 20 countries.

Section I: Global Industry Prospects and Infrastructure Trends

The Increasing Demand for Specialized Mobility Solutions

The global heavy machinery sector is currently witnessing a strategic shift toward specialized mobility. Traditional, fixed-width undercarriages often present logistical challenges when transporting large-scale equipment, such as rotary drilling rigs or mobile stone crushers, through public infrastructure. Market analysis indicates that the demand for "adaptable" crawler foundations is growing at a significant rate. This trend is driven by the rise of urban infrastructure projects where space is confined, and the simultaneous expansion of remote mining operations that require extreme stability on uneven terrain.

Technological Evolution and Autonomous Integration

Modern crawler systems are evolving from simple mechanical frames into sophisticated, integrated platforms.

Remote and Robotic Operations: There is a surge in demand for undercarriages that can support autonomous vehicles, particularly in the disaster relief and hazardous material handling sectors.

Intelligent Hydraulics: The integration of high-torque hydraulic motors with advanced sensor technology allows for precise maneuvering. Extendable systems now frequently incorporate electronic leveling sensors that communicate directly with the machine's primary control unit.

Flotation and Ground Protection: In regions with strict environmental regulations, manufacturers are prioritizing low-ground-pressure designs. This is essential in preventing soil compaction in agricultural zones and minimizing damage to asphalt during urban utility work.

Environmental and Regulatory Drivers

Global sustainability goals are influencing the material science behind crawler manufacturing. The industry is moving toward high-strength, low-weight alloy steels that maintain structural integrity while reducing the overall mass of the machine. This reduction in weight directly correlates to lower fuel consumption and a reduced carbon footprint for the primary equipment. Furthermore, as international trade barriers increasingly focus on quality and safety documentation, manufacturers who can provide certified evidence of their production standards are becoming the preferred partners for global Original Equipment Manufacturers (OEMs).

Section II: The Significance of ISO 9001 in Heavy-Duty Manufacturing

Defining Operational Excellence Through QMS

The ISO 9001:2015 certification is not merely a badge of honor; it is a comprehensive framework that governs the entire Quality Management System (QMS). In the context of producing extendable track systems, this standard ensures that every technical process—from the initial casting of idlers to the high-precision welding of the telescopic beams—is conducted under a disciplined set of guidelines.

Process Consistency: ISO 9001 mandates that manufacturing steps remain consistent across different production batches, ensuring that a client in North America receives the same engineering quality as a partner in Southeast Asia.

Risk Mitigation: By adhering to these standards, a manufacturer can systematically identify potential points of failure in the production line, which is critical when dealing with machinery that carries 120-ton payloads.

Quality Control in Export Operations

For a specialized exporter, the certification acts as a bridge of technical trust. International clients often require documented proof that the steel grade, welding penetration, and hydraulic seal integrity meet global safety benchmarks.

Raw Material Traceability: Every component of the undercarriage, including the track shoes and drive motors, must have traceable material origins to ensure they meet the specific Brinell hardness and tensile strength required for the job.

Export Compliance: ISO standards facilitate easier navigation of customs and safety regulations in diverse markets, as it demonstrates that the product has undergone a recognized audit process.

Continuous Improvement and Customer Focus

A core pillar of the ISO 9001 standard is the "Plan-Do-Check-Act" (PDCA) cycle. This encourages a culture of continuous improvement within the factory. For Yijiang Machinery, this means that customer feedback from diverse environments—such as high-heat mining sites or freezing construction zones—is analyzed and used to refine future designs. This focus on evidence-based decision-making ensures that the extendable mechanisms remain durable over thousands of cycles, preventing hydraulic leaks and mechanical jamming that can occur in less rigorously tested systems.

Section III: Core Competitive Advantages and Product Applications

The "Technical Priority" Customization Framework

Yijiang Machinery distinguishes itself through a "one-to-one" customization model. Unlike suppliers who offer a static range of parts, the factory’s engineering team starts with the client's specific operational parameters.

Dynamic Analysis: The process includes 3D modeling and motor-torque calculations based on the machine's total weight, center of gravity, and climbing slope requirements.

Structural Innovation: The factory's ability to design extendable crossbeams allows for a variable footprint, which is a key technical advantage for machines that must switch between a narrow transport mode and a wide working mode.

Vertical Integration: By managing the entire production cycle in-house, the company maintains total control over quality and lead times, offering factory-direct pricing without middle-party interference.

Main Product Lines and Specialized Niche Markets

The utility of the factory's crawler systems extends across a vast spectrum of industrial applications.

Construction and Mining: High-capacity steel track undercarriages support mobile stone crushers, piling machines, and heavy-duty drilling rigs.

Safety and Disaster Relief: The organization produces reinforced chassis for fire-fighting robots and explosion-proof vehicles, which must navigate debris while resisting high temperatures.

Marine and Environmental Engineering: Specialized underwater crawler parts, equipped with anti-corrosion seals and rotary bearings, are used in seafloor detection and dredging robots.

Agricultural Innovation: Triangle track systems and rubber-tracked chassis are utilized in orchard spraying robots and harvesters to protect soil health and increase traction in muddy fields.

Global Case Success and Client Security

With a reported satisfaction rate of 99%, the factory has successfully completed numerous high-profile projects worldwide. To protect the intellectual property of its global partners, the factory adheres to strict confidentiality protocols and protection agreements, ensuring that proprietary designs remain secure. This commitment to both technical excellence and ethical business practices has established Yijiang Machinery as a strategic partner for equipment manufacturers seeking reliable, high-quality, and certified tracked walking systems.

Conclusion

The evolution of the global crawler machinery market indicates that the future of industrial mobility is rooted in a combination of mechanical flexibility and certified quality. This analysis of the current market trends and the operational standards of a leading manufacturer confirms that achieving ISO 9001 is a critical step in meeting the demands of modern infrastructure. By prioritizing technical support and maintaining a vertically integrated production model, Zhenjiang Yijiang Machinery Co., Ltd. provides the critical foundations required for heavy equipment to operate in the world's most challenging environments. As the sector moves toward further automation and larger capacities, the role of precision-engineered, extendable track systems will remain central to the success of complex engineering projects.

For more information regarding extendable track system specifications, 3D customization services, and technical inquiries, please visit the company's official website: https://www.crawlerundercarriage.com/

Section I: Global Industry Prospects and Infrastructure Trends

The Increasing Demand for Specialized Mobility Solutions

The global heavy machinery sector is currently witnessing a strategic shift toward specialized mobility. Traditional, fixed-width undercarriages often present logistical challenges when transporting large-scale equipment, such as rotary drilling rigs or mobile stone crushers, through public infrastructure. Market analysis indicates that the demand for "adaptable" crawler foundations is growing at a significant rate. This trend is driven by the rise of urban infrastructure projects where space is confined, and the simultaneous expansion of remote mining operations that require extreme stability on uneven terrain.

Technological Evolution and Autonomous Integration

Modern crawler systems are evolving from simple mechanical frames into sophisticated, integrated platforms.

Remote and Robotic Operations: There is a surge in demand for undercarriages that can support autonomous vehicles, particularly in the disaster relief and hazardous material handling sectors.

Intelligent Hydraulics: The integration of high-torque hydraulic motors with advanced sensor technology allows for precise maneuvering. Extendable systems now frequently incorporate electronic leveling sensors that communicate directly with the machine's primary control unit.

Flotation and Ground Protection: In regions with strict environmental regulations, manufacturers are prioritizing low-ground-pressure designs. This is essential in preventing soil compaction in agricultural zones and minimizing damage to asphalt during urban utility work.

Environmental and Regulatory Drivers

Global sustainability goals are influencing the material science behind crawler manufacturing. The industry is moving toward high-strength, low-weight alloy steels that maintain structural integrity while reducing the overall mass of the machine. This reduction in weight directly correlates to lower fuel consumption and a reduced carbon footprint for the primary equipment. Furthermore, as international trade barriers increasingly focus on quality and safety documentation, manufacturers who can provide certified evidence of their production standards are becoming the preferred partners for global Original Equipment Manufacturers (OEMs).

Section II: The Significance of ISO 9001 in Heavy-Duty Manufacturing

Defining Operational Excellence Through QMS

The ISO 9001:2015 certification is not merely a badge of honor; it is a comprehensive framework that governs the entire Quality Management System (QMS). In the context of producing extendable track systems, this standard ensures that every technical process—from the initial casting of idlers to the high-precision welding of the telescopic beams—is conducted under a disciplined set of guidelines.

Process Consistency: ISO 9001 mandates that manufacturing steps remain consistent across different production batches, ensuring that a client in North America receives the same engineering quality as a partner in Southeast Asia.

Risk Mitigation: By adhering to these standards, a manufacturer can systematically identify potential points of failure in the production line, which is critical when dealing with machinery that carries 120-ton payloads.

Quality Control in Export Operations

For a specialized exporter, the certification acts as a bridge of technical trust. International clients often require documented proof that the steel grade, welding penetration, and hydraulic seal integrity meet global safety benchmarks.

Raw Material Traceability: Every component of the undercarriage, including the track shoes and drive motors, must have traceable material origins to ensure they meet the specific Brinell hardness and tensile strength required for the job.

Export Compliance: ISO standards facilitate easier navigation of customs and safety regulations in diverse markets, as it demonstrates that the product has undergone a recognized audit process.

Continuous Improvement and Customer Focus

A core pillar of the ISO 9001 standard is the "Plan-Do-Check-Act" (PDCA) cycle. This encourages a culture of continuous improvement within the factory. For Yijiang Machinery, this means that customer feedback from diverse environments—such as high-heat mining sites or freezing construction zones—is analyzed and used to refine future designs. This focus on evidence-based decision-making ensures that the extendable mechanisms remain durable over thousands of cycles, preventing hydraulic leaks and mechanical jamming that can occur in less rigorously tested systems.

Section III: Core Competitive Advantages and Product Applications

The "Technical Priority" Customization Framework

Yijiang Machinery distinguishes itself through a "one-to-one" customization model. Unlike suppliers who offer a static range of parts, the factory’s engineering team starts with the client's specific operational parameters.

Dynamic Analysis: The process includes 3D modeling and motor-torque calculations based on the machine's total weight, center of gravity, and climbing slope requirements.

Structural Innovation: The factory's ability to design extendable crossbeams allows for a variable footprint, which is a key technical advantage for machines that must switch between a narrow transport mode and a wide working mode.

Vertical Integration: By managing the entire production cycle in-house, the company maintains total control over quality and lead times, offering factory-direct pricing without middle-party interference.

Main Product Lines and Specialized Niche Markets

The utility of the factory's crawler systems extends across a vast spectrum of industrial applications.

Construction and Mining: High-capacity steel track undercarriages support mobile stone crushers, piling machines, and heavy-duty drilling rigs.

Safety and Disaster Relief: The organization produces reinforced chassis for fire-fighting robots and explosion-proof vehicles, which must navigate debris while resisting high temperatures.

Marine and Environmental Engineering: Specialized underwater crawler parts, equipped with anti-corrosion seals and rotary bearings, are used in seafloor detection and dredging robots.

Agricultural Innovation: Triangle track systems and rubber-tracked chassis are utilized in orchard spraying robots and harvesters to protect soil health and increase traction in muddy fields.

Global Case Success and Client Security

With a reported satisfaction rate of 99%, the factory has successfully completed numerous high-profile projects worldwide. To protect the intellectual property of its global partners, the factory adheres to strict confidentiality protocols and protection agreements, ensuring that proprietary designs remain secure. This commitment to both technical excellence and ethical business practices has established Yijiang Machinery as a strategic partner for equipment manufacturers seeking reliable, high-quality, and certified tracked walking systems.

Conclusion

The evolution of the global crawler machinery market indicates that the future of industrial mobility is rooted in a combination of mechanical flexibility and certified quality. This analysis of the current market trends and the operational standards of a leading manufacturer confirms that achieving ISO 9001 is a critical step in meeting the demands of modern infrastructure. By prioritizing technical support and maintaining a vertically integrated production model, Zhenjiang Yijiang Machinery Co., Ltd. provides the critical foundations required for heavy equipment to operate in the world's most challenging environments. As the sector moves toward further automation and larger capacities, the role of precision-engineered, extendable track systems will remain central to the success of complex engineering projects.

For more information regarding extendable track system specifications, 3D customization services, and technical inquiries, please visit the company's official website: https://www.crawlerundercarriage.com/

Zhenjiang Yijiang Machinery Co., Ltd.

Zhenjiang Yijiang Machinery Co., Ltd.

13862448768

manager@underpan.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.